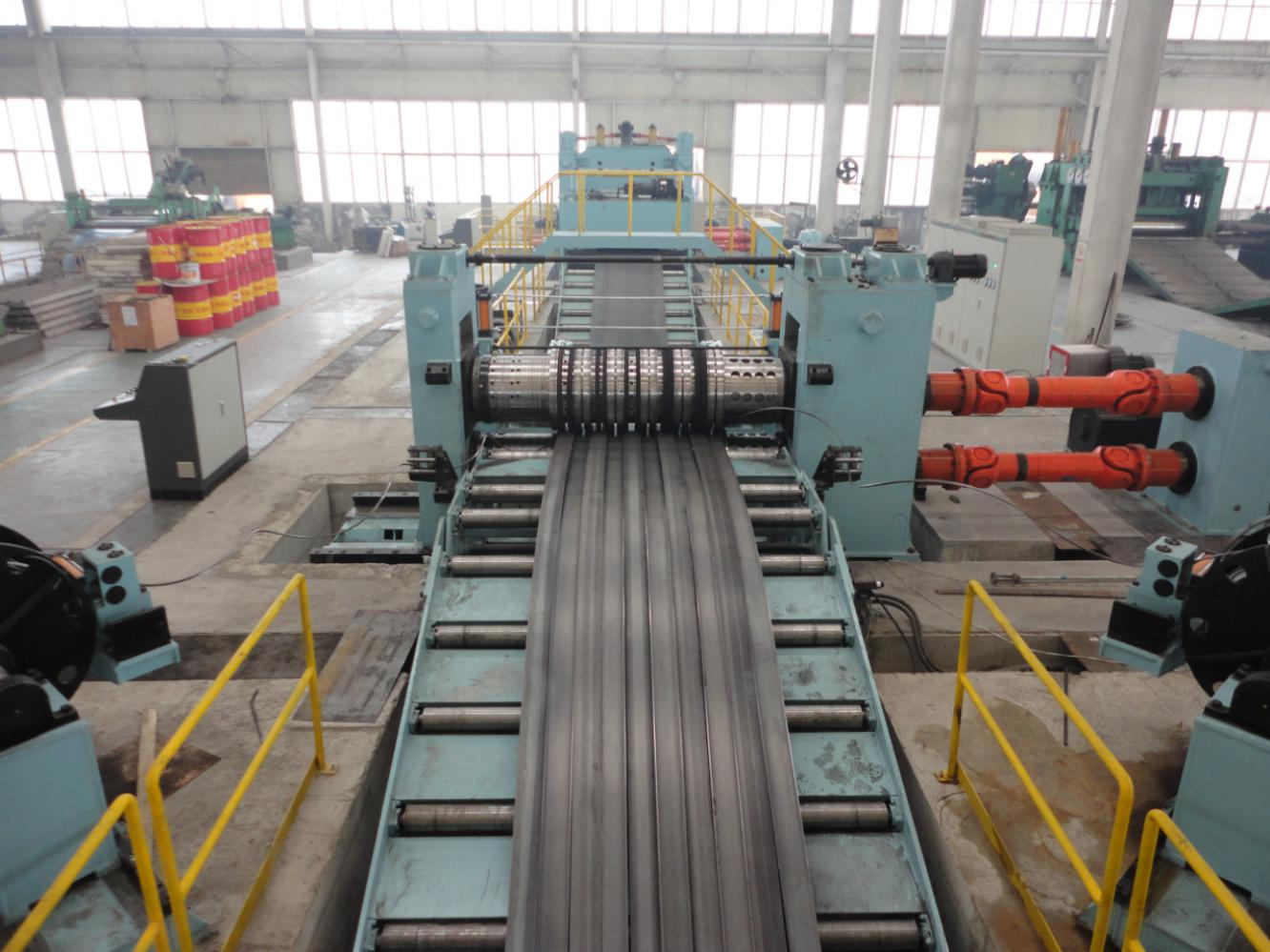

Cut to length and slitting machine

\n(1~12mmT×2000mmW×32Ton×30/100mpm)

\n

\n

\nSpecification of Production Line

\n1.Main technical parameters

\nA、 Unit data:

\n1、Equipment Name:CNC Coil Uncoiling Slitting Recoiling Line

\n2、Model:SL-12×2000

\n3、Technological Process:

\nprepare coil→Loading car →Uncoiling →Feeding →pinch →pre-leveling →Hyd-shear→ Roller table →Side guide→ Slitting → Scrap winding →looper →Separating → Tension →Feeding →Snubber →Recoiling → Unloading

\nB、Processing Material Parameters:

\na)Inlet Material Parameters:

\nmaterial Performance:HR. Steel Coil(YS.≤250MPa,TS.≤480MPa)

\ncoil thickness:1mm~12mm(Leveling + Shear)

\nCoil Width:800mm~2000mm

\nCoil Inner Diameter:Φ610mm;

\nCoil Outer Diameter:Φ1300mm~Φ2200mm

\nCoil Weight:Max.32000Kg

\n2)Finish Product:

\nRecoil ID:Φ610mm

\nRecoil OD:Φ1300mm~Φ2200mm

\nRecoil Weight:Max.32000Kg

\nStrip slitting capacity:

\nMax.15 strips(Coil thickness 2mm)

\nMax.10 strips(Coil thickness 4mm)

\nMax.6 strips(Coil thickness 6mm)

\nMax.4 strips(Coil thickness 8mm)

\nSlitting width:Min.80mm

\nWidth accuracy:±0.2mm

\nSickle curve:≤0.5mm/1000mm(Coil width≥200mm)

\nShear burr:≤4%*thickness

\nScrap Width:5~15mm

\nCoiling tolerance:Pyramid ≤±10mm;

\n2.Machine list:

\n\n\n\n\n\n\n\n\n\nNo.

\n\n\nUnit Name

\n\n\nQty(Set)

\n\n\nRemark

\n\n\n\n\n1

\n\n\nCoil Saddle

\n\n\n1

\n\n\n

\n\n\n\n\n2

\n\n\nLoading Car

\n\n\n1

\n\n\n

\n\n\n\n\n3

\n\n\nDouble - heads uncoiler

\n\n\n1

\n\n\n

\n\n\n\n\n4

\n\n\nGantry feedind device

\n\n\n1

\n\n\n

\n\n\n\n\n5

\n\n\nPre-leveler (2+5 rollers)

\n\n\n1

\n\n\n

\n\n\n\n\n6

\n\n\nHydraulic shear+Scrap Car

\n\n\n1

\n\n\n

\n\n\n\n\n7

\n\n\nRoller table

\n\n\n1

\n\n\n

\n\n\n\n\n8

\n\n\nHydraulic Side Guide

\n\n\n1

\n\n\n

\n\n\n\n\n9

\n\n\nSlitter

\n\n\n1

\n\n\n

\n\n\n\n\n10

\n\n\nScrap Winder

\n\n\n1

\n\n\n

\n\n\n\n\n11

\n\n\nLooper

\n\n\n1

\n\n\n

\n\n\n\n\n12

\n\n\nSeparation Device

\n\n\n1

\n\n\n

\n\n\n\n\n13

\n\n\nTension and Feeding Mechanism

\n\n\n1

\n\n\n

\n\n\n\n\n14

\n\n\nRecoiler+Separating

\n\n\n1

\n\n\n

\n\n\n\n\n15

\n\n\nUnloading Car

\n\n\n1

\n\n\n

\n\n\n\n\n16

\n\n\nOil hydraulic system

\n\n\n1

\n\n\n

\n\n\n\n\n17

\n\n\nPneumatic System

\n\n\n1

\n\n\n

\n\n\n\n\n18

\n\n\nElectrical Control System

\n\n\n1

\n\n\n

\n\n\n\n\n19

\n\n\nUnit Protection Facilities

\n\n\n1

\n\n\n

\n\n\n\n\n20

\n\n\nAccessories: Slitting knives, spacer bushing, rubber sleeve, separation disk, etc

\n\n\n1

\n\n\n

\n\n\n\n\n\n\n\n\n","desc":"Slitting Line ZSCL-12×2000

\n(1~12mmT×2000mmW×32Ton×30/100mpm)

\n

\n

\nSpecification of Production Line

\n1.Main technical parameters

\nA、 Unit data:

\n1、Equipment Name:CNC Coil  ...","date":"2024-09-05","visits":0,"color":"","category":"Products","sname":"","slink":"https://wgbxdskzo.okkishop.site/cut-to-length-and-slitting-machine","tag":"","down":"","downname":"","downurl":"","prev":{"cid":96,"c_sid":51,"c_title":"H Beam Production Line","c_pic":"https://shopcdnpro.grainajz.com/category/365232/2148/47e8343d874dbc63434a894cb74eb1a3/2.jpg","c_pagename":"/h-beam-production-line","c_link":""},"next":{"cid":94,"c_sid":51,"c_title":"C Z Ω purlin forming machine","c_pic":"https://shopcdnpro.grainajz.com/category/365232/2148/d727f1fe0343940564980141186afe88/68AE86C2A412C2D178DDAF92B5F774EE.jpg","c_pagename":"/c-z--purlin-forming-machine","c_link":""},"count":1,"specs":[],"skus":[],"product_summary":"","product_image_video":"","brand_manufacturer":"","product_code_spu":"","extension_title":"","extension_content":[{"extension_title":"","extension_content":""}],"product_price":"0.00","need_show_price":0}

Introduction

Slitting Line ZSCL-12×2000

(1~12mmT×2000mmW×32Ton×30/100mpm)

Specification of Production Line

1.Main technical parameters

A、 Unit data:

1、Equipment Name:CNC Coil Uncoiling Slitting Recoiling Line

2、Model:SL-12×2000

3、Technological Process:

prepare coil→Loading car →Uncoiling →Feeding →pinch →pre-leveling →Hyd-shear→ Roller table →Side guide→ Slitting → Scrap winding →looper →Separating → Tension →Feeding →Snubber →Recoiling → Unloading

B、Processing Material Parameters:

a)Inlet Material Parameters:

material Performance:HR. Steel Coil(YS.≤250MPa,TS.≤480MPa)

coil thickness:1mm~12mm(Leveling + Shear)

Coil Width:800mm~2000mm

Coil Inner Diameter:Φ610mm;

Coil Outer Diameter:Φ1300mm~Φ2200mm

Coil Weight:Max.32000Kg

2)Finish Product:

Recoil ID:Φ610mm

Recoil OD:Φ1300mm~Φ2200mm

Recoil Weight:Max.32000Kg

Strip slitting capacity:

Max.15 strips(Coil thickness 2mm)

Max.10 strips(Coil thickness 4mm)

Max.6 strips(Coil thickness 6mm)

Max.4 strips(Coil thickness 8mm)

Slitting width:Min.80mm

Width accuracy:±0.2mm

Sickle curve:≤0.5mm/1000mm(Coil width≥200mm)

Shear burr:≤4%*thickness

Scrap Width:5~15mm

Coiling tolerance:Pyramid ≤±10mm;

2.Machine list: